Shipping

Shipping Done Simply

Save Time and Money

SAVE TIME AND MONEY! Use our account to pick up your package directly from your facility. Simply call our office with the dimensions and weight of the box and UPS will show up with a label.

Proper preparation of your hides will ensure best outcome for your hides. Folding correctly will prevent cracks and breaks on face, feet and tail.

Instructions

Salt, Fold, & Pack Hides

1. Salt

- Generously apply first salting to both sides for 24 hours. Best practice is to rub into leather.

- Shake off extra salt.

- Second salting for an additional 24 hours.

- After second salting, hang hair side-down over wooden 2×4 or PVC 2-inch pipe. Make sure pole or pipe is off ground, preferably hung mid neck.

- When skin whitens (80% dry) with slight flexibility, fold cape as seen on instructions below.

2. Fold

Step 1

Step 2

Step 3

Step 4

3. Pack

Fill out a shipping form and put it inside of the box and keep a copy for yourself. You can always call us if you need shipping forms.

Properly folding your hides will help with the quality of your hides. It is also important because it allows more skins to fit inside each box.

- Lay sheets of newspaper or craft paper between each skin. Paper absorbs moisture and repels heat.

- Stuff inside corners of box by wadding up paper and fill the in inside corners of box and securely fasten box or crate. Newspaper will help keep skins from shifting within box during shipping.

- Only dry salted skins are accepted.

- Skins that are wet and in plastic bag are not accepted. Bacteria/mold will grow and potential issues such as slippage may become a concern.

If we receive a box with live bugs we are required to spray to treat the bugs.

If there are excessive bugs, the box will be returned to sender and additional fees may be applied.

For shipping large quantities in pallets or crates, please read instructions for large shipments.

4. Final Steps

Once you have finished packing your hides, call our office with dimensions and weight. Don’t forget to fill out our shipping form to instruct on which service you want for your hides. Place the form inside or on top in plastic slip. Make sure labels are placed well on the crate (preferably on more than one surface if possible). Ensure you keep a copy of all paperwork and we always recommend to take pictures of your fright before it leaves your facility or once it’s loaded onto the truck. We will need to know if pickup is in a residential area and if a lift gate will be needed.

To avoid additional fees, it is important to provide most accurate information for weight and dimensions. The shipping company will always measure and if they have adjusted or reclassify it will incur additional charges.

We are more than happy to walk you through the process, just give us a call!

Large Shipments

Instructions for Shipping Large Quantities

Ship in Pallets or Crates

You have the option to ship pallets or crates to our facility. We can always schedule LTL Freight Shipments or send you over a quote. Shipments must be on a pallet or you can place 2×4 wood panels underneath for enough clearance for a pallet jack to be used.

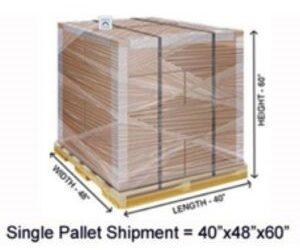

- Suggested pallet size 48″ x 40” inches or less.

- Pallet height six feet (72”) and under for best pricing. Max height allowed is eight feet (96”)

- Do not select pallets with broken boards or protruding nail heads.

- Any lids on crates or wood boxes will need to be secured with screws, not nails.

- ALWAYS take a picture of your shipment when it leaves your facility.

Save a pallet for a later date, purchase from freight supplier or Uline.com

Protect Your Palletized Shipment from Damage

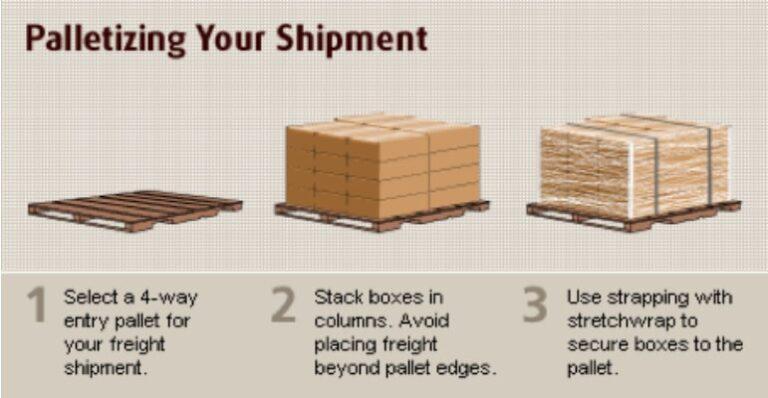

- Stack boxes together carefully. Heavier boxes go on the bottom, and lighter boxes go on the top. Make sure none of the boxes overhang the pallet and that they aren’t misaligned. Try to make sure the weight is evenly distributed within each box and on each layer of the pallet.

- Use corner beads and edge protectors to fortify the pallet. They protect the shipment from bending, increase vertical stacking strength, prevent damage to edges, and stabilize the load. They should extend to the full height and length of the load and should be used on all corners.

- Shrink wrap your load three to five times (five times is recommended). Make sure your shrink wrap is 60 gauge or heavier. Twisting the shrink wrap while wrapping the load will give the shrink wrap more strength.

- Strap your load to the pallet to secure your shipment. Strapping should be drawn tightly to the load, which may require running the straps underneath the pallet’s top deck boards.